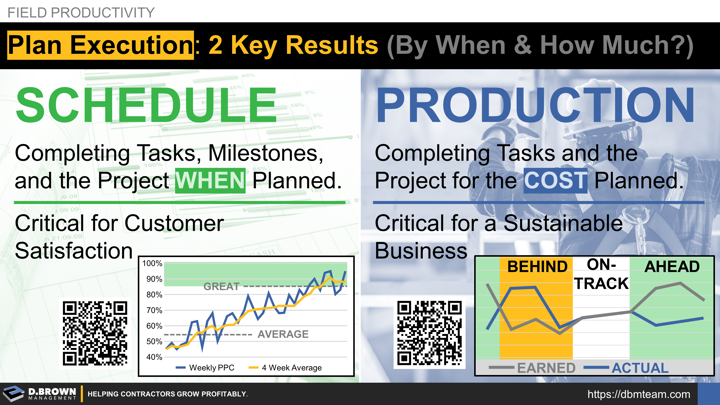

- SCHEDULE: Completing tasks, milestones, and projects WHEN planned.

- PRODUCTION: Completing tasks, milestones, and projects for the COST planned.

These are interrelated but are different. You can achieve scheduled milestones by throwing resources at the problem but that is not sustainable if production budgets are continuously missed.

You will find that by focusing on the scheduling aspect first provides the stability and predictability to continuously improve each week. This is a large part of the feedback and learning process for project.

The heart of execution at both the schedule and production level starts with defining effective tasks and managing the 6 Pillars of Productivity with rigorous ABC Daily Planning.

By reviewing scheduled feedback weekly, you'll likely find that most of the things that impact scheduling are outside of your direct control. Each week you will learn what really matters most and how to improve your ability to influence the outcomes.

These two key results assume basics like quality and safety are a non-negotiable part of the culture.