I learned this lesson from two superintendents from two different general contractors who were building identical projects in different parts of town in 1990.

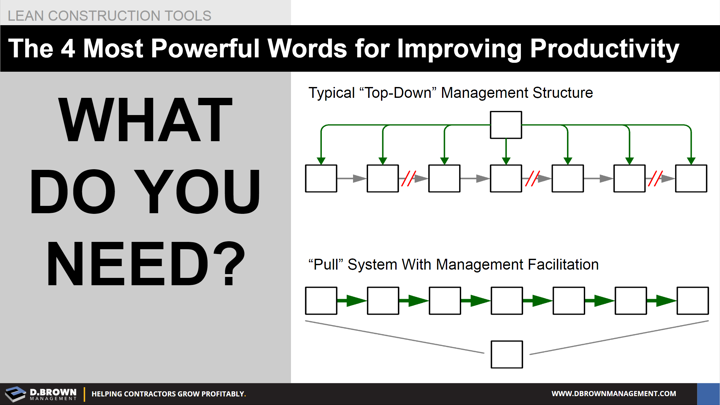

One superintendent was very experienced and directed all of the subcontractors on what to do. The other superintendent had almost no experience and would get all the subcontractors together in his trailer looking at the project schedule together on the wall. He would then pull out his notepad and start asking each of us “What do you need?” He wrote it all down and worked hard to get us what we needed so we could do our work effectively.

The project with the less experienced superintendent finished 3 months earlier with less change orders!

In 1990 the term lean was only starting to get used in the world as a whole based on a paper written by John Krafcik in 1988. It wasn’t until 1997 that the Lean Construction Institute was founded and their flagship tool called the Last Planner System was introduced.

Lean tools and the Last Planner System really just codify what the best superintendents and managers have been doing creating a scalable system.

Pull Planning is a lean construction practice.