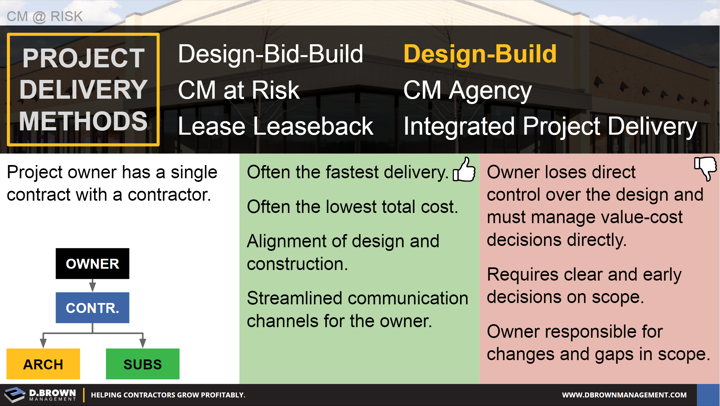

The Design-Build method of project delivery eliminates a couple of the major negatives inherent in the Design-Bid-Build method.

This integrates construction and design by putting the contractor fully in charge of the process which shortens delivery timelines and substantially cuts change orders.

A study by Penn State and the Construction Industry Institute (CII) in 1997 showed many of the advantages of the Design-Build method, which are summarized in these slides from the Design-Build Institute of America (DBIA).

The key downsides of Design-Build include:

- The project owner loses direct control over the design and must directly manage value vs. cost decisions.

- The project owner must have clear and complete decisions on the scope of the project very early on.

- The project owner is responsible for changes and gaps in the scope. Deeply understanding the architectural design process and knowing how to manage it is a critical skill for any contractor delivering preconstruction services.