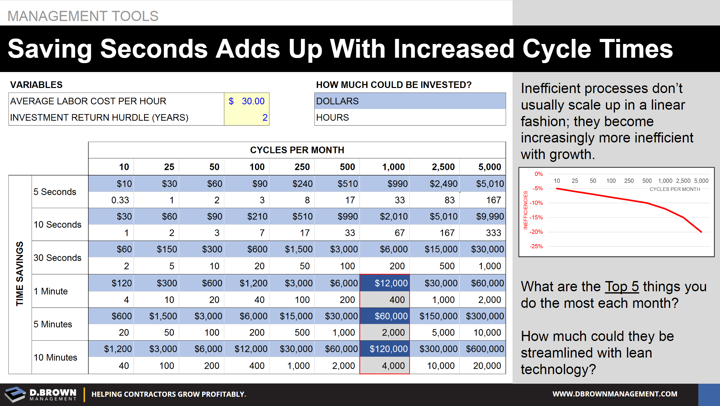

Saving 5 minutes per cycle for something done 100 times per month is only worth $6,000 over a couple years. At 1,000 cycles per month it’s worth investing up to $60,000 to make the process more efficient.

Too many times as contractors scale they look primarily at the technology tools and get poor results. One factor often underestimated is the investment in rolling out the new standards versus just the cost of the technology.

Corbins Electric and NOX Innovations are really good at is looking at the whole workflow, talent, culture and technology. They give a great example of this with their purchasing process improvement.

Everything stated here seems easy enough but is VERY difficult to execute consistently. The team at Corbins has done an amazing job balancing high-level strategic direction, culture and process streamlining. They are also great about sharing with their peers in the industry.