- The project schedule for other trades and tasks must be adjusted often, causing overall project delays, increased “Bad Stress” on the project team, or both.

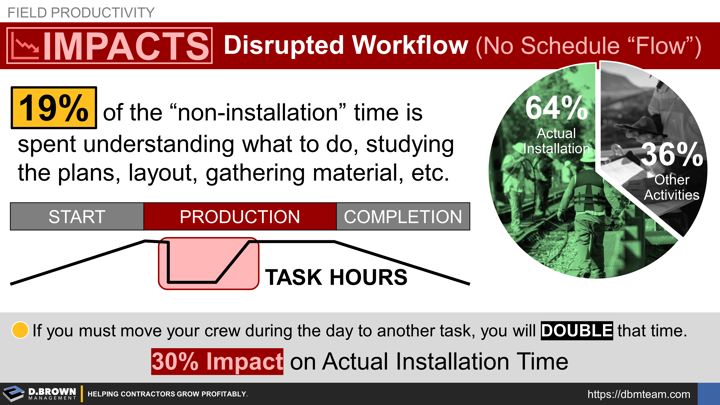

- The actual task itself costs more than budgeted by contractor. At a minimum, the interruption will cost additional mobilization to and from the work area. Remember that about 19% of the labor hours in a typical construction day are spent figuring out what to do, gathering materials, and site movement. When a task is interrupted, you often have to repeat some or all of these non-installation tasks.

When this happens frequently, it starts to impact every aspect of the contractor’s scoreboard in a negative way starting with customer satisfaction.

Weekly feedback and learning systems are a core element of the Last Planner System because their research showed that tasks not being completed as planned were the single biggest source of poor project performance.

Focusing on planning Effective Tasks, the 6 Pillars of Productivity, and ABC Daily Planning will keep your project on-track.