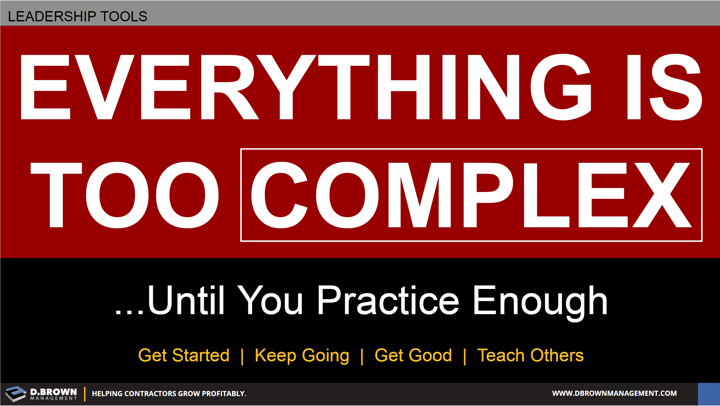

Supply chains are more complex. Technology is more complex. The world is becoming more complex. We don’t do ourselves or others any favors by not coming to terms with that complexity.

Simplification and streamlining should always be our goal. We must get comfortable learning the complexities before we can work on simplification.

“Seek first to understand, then to be understood.”

- Stephen R. Covey | 7 Habits of Highly Effective People

“Often we don't need better ideas, we just need to frame them more effectively. To describe something simply, you must really understand it deeply."

How would you answer the following questions yes or no?

- I believe some processes and tools are too complicated in my company.

- I did my best today to deliberately practice using those process and tools.

- I did my best today to improve and document new standards using the PDCA and 5S tools.

- I did my best today to share what I learned by teaching someone else.

If you answer those questions every day for a month what would your ratio be of yes vs. no?

If your team answered them what would that ratio be?