None of us were born with great business acumen, people skills or technical competency. Each of us has developed both mental and physical skills over time. We may not even realize how we got developed so we tend to believe that we were just born a certain way.

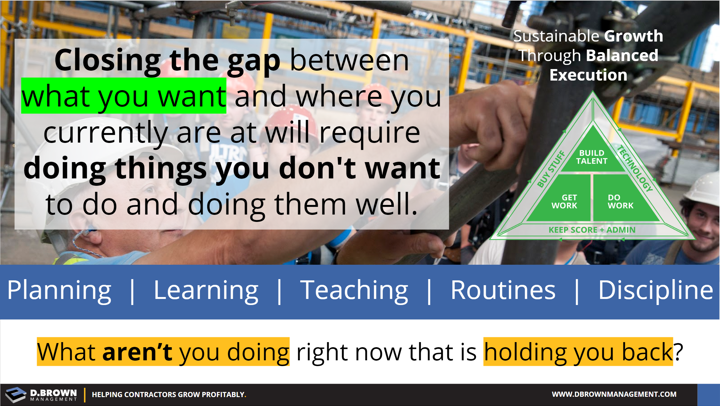

So far they have not discovered the “Great Contractor Gene.” More current research on topics such as neuroplasticity have shown that our brains continue to change throughout our lives if we train effectively. Using techniques such as “Deliberate Practice” while difficult have proven very effective in developing people at all levels. These techniques are difficult much like a physical workout and require us doing things we really don’t want to do. However over time as a weakness becomes a strength we usually start to love doing it.

Learn More:

Books:

As we are helping contractors prepare to take advantage of the opportunities the talent shortage will provide over the next decade we have learned a lot of lessons about how teams develop.

This is a broad, deep and important topic impacting growth, succession and even viability for all contractors.

Contact us to discuss lessons we have learned working with many teams.