It is how we choose to use those resources that determines the level of our success, the speed we get there and our joy while on the journey.

- Spend time developing your strategy and determining what really matters in helping you get there.

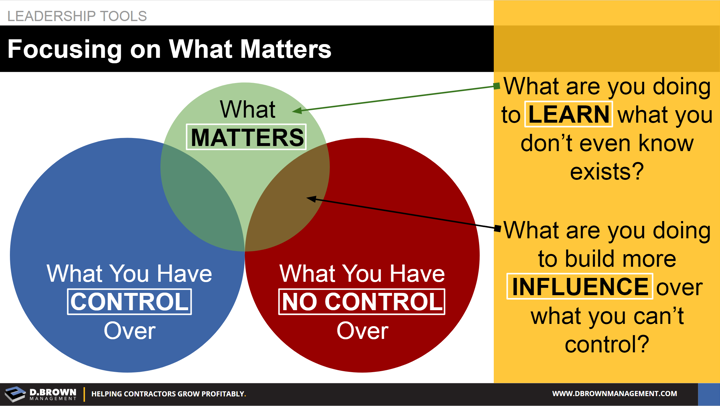

- Assume your mental model of what really matters is incomplete.

- Assume that you have more control than you think. Stephen Covey gives a great example of expanding your Circle of Influence in this 3 minute video which is expanded upon more in the book 7 Habits of Highly Effective People.

- Assume this will take a while but everything worth achieving takes time. Success is about taking a series of smooth and deliberate steps in the right direction every day. Remain focused on the objective. Don’t get sidetracked by momentary obstacles or setbacks. Learn from the Marshmallow Experiment.

Assess yourself over the last week:

- How much time did you spend on things you can control but don’t really matter?

- How much time did you spend thinking or complaining about things you can’t control?

- How much time did you spend developing a more accurate model - learning what you didn’t even know you needed to learn?

- How much time did you spend prioritizing around what really matters?

- How much time did you spend working to build more influence over those areas where you currently have no control that truly matter?